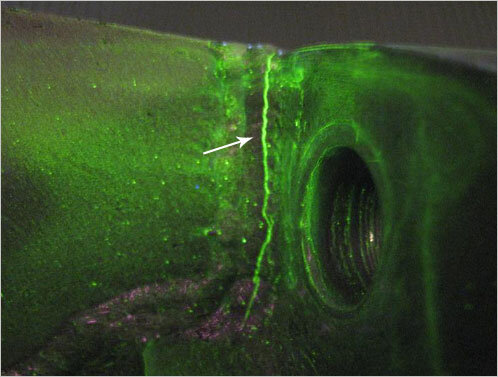

Fluorescent Penetrant Inspection

Fluorescent penetrant inspection (FPI) is a type of dye penetrant inspection in which a fluorescent dye is applied to the surface of a non-porous material in order to detect defects that may compromise the integrity or quality of the part in question.

Fabrivision Flatbed 2D Scanning

FabriVISION Laser is a high-tech, laser-based inspection machine that will increase your inspection performance, quality control processes, production capacity and overall profitability. In use for over 20 years by more than 500 customers worldwide, the FabriVISON inspection series is a mature, proven tool for the validation of sheet metal parts. FabriVISION laser will reduce your first article inspection time up to 96% while at the same time increasing the accuracy of inspections by eliminating costly human errors in measurement. What might have taken hours in the past will now take minutes to complete. FabriVISION Laser increases the green light time of your shop’s machines by decreasing first-article inspection time and expensive quality control processes.

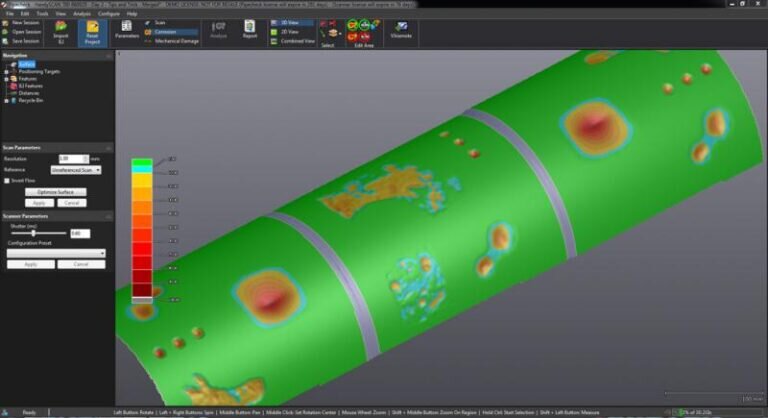

Creaform 3D Laser Scanning

3D scanning, the process of converting physical objects into precise digital models, enables you to quickly and accurately capture your project’s shape and geometries. This process supplies you with a complete digital representation of your part to be used for reverse engineering, quality inspection or at any point of a typical manufacturing cycle. 3D laser scanning technology can provide you with:

- Fast, ultra-accurate results, reducing your time to market (saving you time and money!)

- Complete measurement data of the entire surface of your object, verifying that the as-built part matches your CAD model

- True CAD models for FEA testing of actual geometry to correct problems before parts go into production

- CAD models to validate tooling, even when no current models exist

- Profile data of the whole part so assemblies can be digitally put together, revealing inaccuracies and interference

Niton™ XL2 Plus Handheld XRF Analyzer

When you need nondestructive testing with results in seconds for metal analysis, mining and exploration, and lead paint testing for toys and consumer goods, the Thermo Scientific™ Niton™ XL2 Plus XRF Analyzer is the definitive tool for scrap metal recycling, casting and fabrication, manufacturing QA/QC and positive material identification. Get real-time compliance testing, including screening of incoming materials and outgoing finished goods, for the Consumer Product Safety Improvement Act (CPSIA), Proposition 65, Restriction of Hazardous Substances (RoHS) and other regulations.